Company History

Since the founding of the parent company "Photo-Sonics, Inc." as the "ACME Tool & Manufacturing Company" in the USA nearly a century ago, the company's expertise has transitioned from manufacturing cameras and animation stands for Walt Disney, to providing flight test and other specialised instrumentation to a wide range of commercial and academic customers.

This is the story of how it all happened.

The Masters of Animation

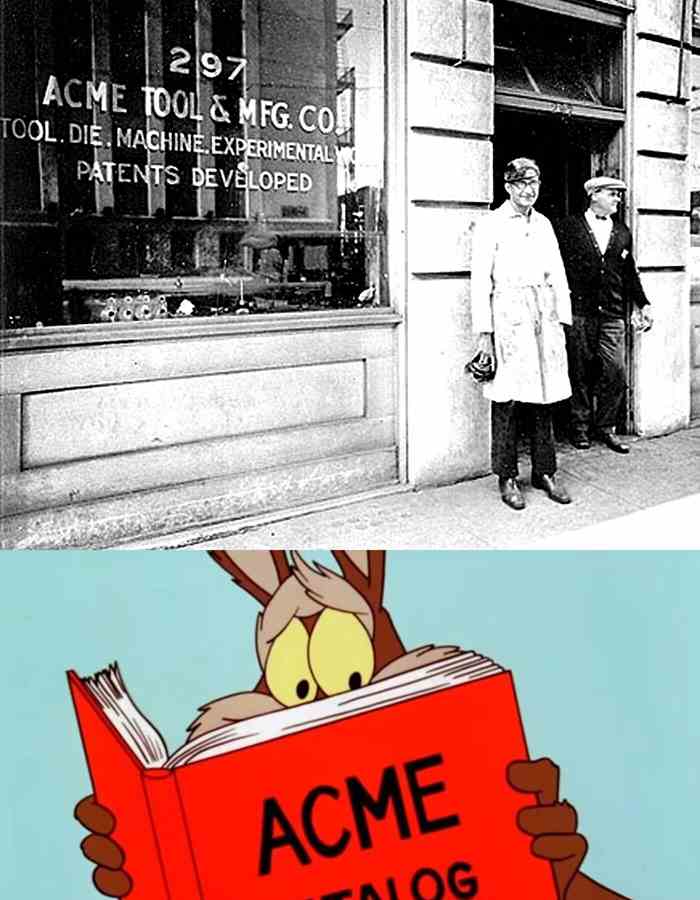

In the late 1920's Adolph Furer founded the business as "ACME Tool and Manufacturing Company". The company began primarily as a contract machine shop. In ensuing years the company moved into the motion picture field through contact with Walt and Roy Disney. The Disney's were in a specialized and entirely new field of photography for which appropriate equipment, including animation cameras, were not available.

Walt Disney requested that Adolph Furer modify existing cameras for the production of animation. Instead Adolph's company elected to manufacture a proprietary camera, and thus the first ACME Camera was designed and manufactured.

Soon the company was designing and manufacturing all the equipment required for the production of animation including Cameras, Motors, Cell Punches, animation boards and complete Animation Stands. The name ACME became synonymous with the production of animation.

Whilst we never made any rocket-powered roller skates, the popular cartoon series featuring Wile E. Coyote and the Road Runner was produced with ACME animation equipment and the animation artists at Warner Brothers put our name in their cartoon.

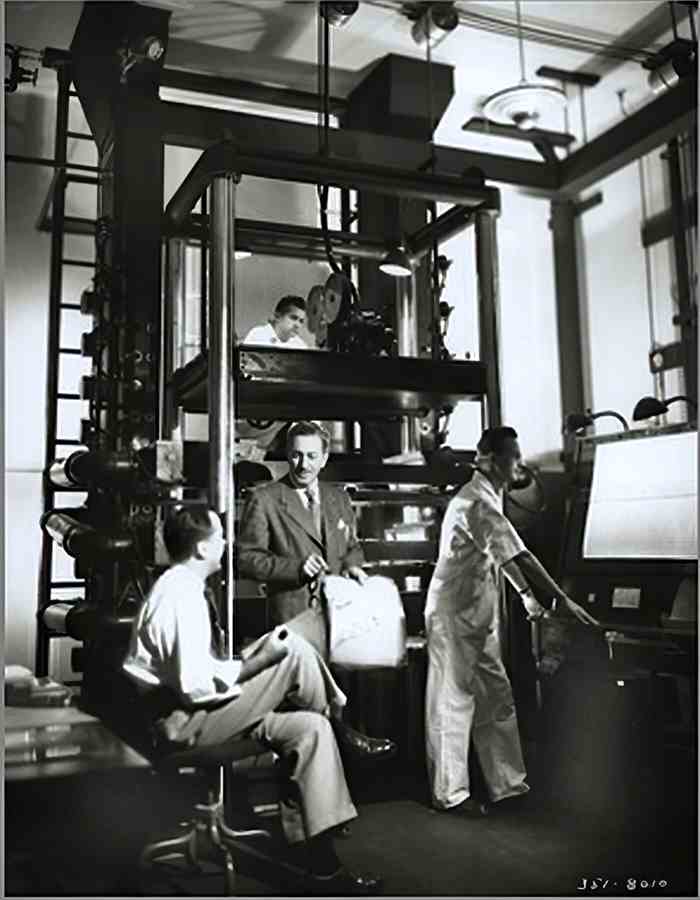

In 1936 ACME manufactured the parts for Disney's Multi-plane Camera. This bespoke camera was used for the production of Snow White and the Seven Dwarfs. The project was kept a secret until 1956 when Walt Disney finally revealed how his 3D cartoon effects were produced.

ACME Tool & Manufacturing Co., 1920's, and their most prestigious customer.

ACME Camera Model 5 - 1928

Disney's Multi Plane Camera build by ACME.

Special Effects & High Speed Cameras

In 1939 Adolph Furer sold his interest to his son, Edward, who oriented the business toward the development and manufacture of special effects motion picture equipment.

That same year the company collaborated with Special Effect pioneer Linwood Dunn to develop the ACME-DUNN Optical Printer. The development was funded ACME’s first U.S. Government contract.

The optical printer remained the foundation of visual effects until the mid 1990s, when digital compositing became feasible.

During his career, Dunn provided special effects for over one hundreds movies and television programs including the original King Kong in 1933, Citizen Kane, West Side Story, 2001: A Space Odyssey and the Star Trek television series. He continued his influential career until his death in 1998.

In 1949, and in line with this shift in direction, Edward changed the company name to "Producers Service Company".

The company continued to design and manufacture custom optical film printers for Universal, 20th Century-Fox, Cinerama, Todd-AO, Consolidated Film Industries, Pathe, Eastman Kodak, Rank Studios, Disney, Warner Brothers, Columbia Pictures, Hanna Barbera and many others in to the 1960's.

In 1968 Photo-Sonics designed and manufactured the 35mm-4E camera which became an instant favourite for the production of high speed special effects for motion pictures and television commercials. Following the use of the 4E on the movie "Tora Tora Tora" (A 1970 US movie based on the Japanese attack on Pearl Harbour in 1941), Photo-Sonics began a rental division specializing in high speed cameras and accessories.

In 1980, Linwood Dunn and the owner of Photo-Sonics (ACME) were presented with Academy Awards for the development of the ACME-DUNN Optical Printer. Linwood’s personal ACME DUNN optical printer is currently on display at the Academy of Motion Picture Arts and Science’s Linwood Dunn Theatre in Hollywood.

In 1988, Photo-Sonics, Inc. was again awarded a Scientific and Engineering Award from the Academy of Motion Picture Arts and Sciences© for the design of the 4ER 35mm High-Speed film camera. The award was presented to Mr. Roy Edwards and the Engineering Staff of Photo-Sonics, Inc.

ACME DUNN optical printer and Oscar

ACME Photo-Sonics High Speed Camera

Rockets, Planes, and Automobiles

With the start of the cold war in the late 1940’s, the U.S. Government became increasingly interested in atomic bomb and missile development. Those testing the new weaponry wished to see what was happening in detail, and thus began looking for someone to build them high speed cameras. ACME were recommended and their success led to the formation of “Photo-Sonics Inc.” in 1952.

Continuous development by Photo-Sonics of the high speed camera led to them become the first choice in both military and civil applications. Within the movie industry, as we saw above, they were used in most block busters of the day. These included such iconic films as Star Wars, Raiders of the Lost Ark, The Terminator and Top Gun. And in a twist of fate, it is rumoured the acclaimed director Christopher Nolan used a Photo-Sonics 35mm-4C Camera capable of 2500 frames a second, to film scenes in his 2023 bio-pic Oppenheimer, about the development of the nuclear bomb.

NASA called upon Photo-Sonics to develop cameras to film rocket launches. These included 40 16mm-1PL cameras that were mounted on the Space Shuttle gantry and more around the launch pad. It was a Photo-Sonics 70mm-10A camera that provided 10 frames recording the cause of the ill fated Space Shuttle Challenger in 1986.

Photo-Sonic high speed cameras were used by the Ford Motor Company for recording impacts in car crash testing. And Carl Boenish, the father of Base Jumping acquired footage of his exploits from a Photo-Sonics 1VL fastened to his helmet.

Sticking with aviation, and those of a longer flight time, the 16mm-1VN, a pin registered 200 fps high speed camera was used for flight testing of fighter aircraft and stores release.

All the way back to the late 1960’s, and continuing to this day, Photo-Sonics began winning contracts to supply Heads Up Display cameras to the military jets including the Alpha Jet, Warthog, F-4, F-15, F-16 and F-18.

Space Shuttle Launch

Photo-Sonics 16mm-1VN High Speed Camera

Photo-Sonics HUD Camera In F 18 Super Hornet

Optical Tracking

Whilst simultaneously working with the film and aerospace industry on high speed cameras, work commenced in the mid 1960's to replace the modified gun-turrets the U.S. Navy were using to acquire optical data from missile launches. In 1965, the company delivered the first Cine-Sextant Optical Tracking Mount to the U.S. Navy at Point Mugu. Over the next years Photo-Sonics Inc. manufactured and delivered 100 Cine-Sextants to foreign and domestic optical ranges around the world.

In 1971 the company delivered the Mirror Mount Tracking Systems for the test and evaluation of the Sprint Missile System. The Mirror Mount had 2200 degrees per second per second acceleration.

At the Kwajalein Test Range (now called the Ronald Reagan Ballistic Missile Defense Test Site) in the South Pacific, Photo-Sonics had installed six Super-RADOT by the mid 1970's for the test and evaluation of Inter-continental Ballistic Missiles (ICBM). These systems were able to acquire the ICBMs up to 1600 miles down range and track multiple missiles as they re-entered the atmosphere at 17,000 miles per hour. The Super-RADOT were used to test the accuracy of the weapon system. An array of five Super-RADOT systems provide 3 arc-second accuracy and are considered amongst the most accurate long range tracking systems in the world.

In 2007, Photo-Sonics won a competitive award to develop a high-performance tracking system to evaluate hyper-velocity targets that travel at a velocity of 2,000 metres/second. The system tracks the projectiles from launch to impact and provides 3D position data accurate to within two metres at 10 kilometre in real time and within one metre at 10 kilometres after post processing of the data and images. The system also includes built-in post processing software that provide high-accuracy TSPI data within minutes of the event. The system was delivered in September 2010.

Photo-Sonics Inc. continue to develop and advance the technology in Optical Tracking Systems, and in September 2021 delivered the first two ARTIS/MITS Fly-Out Optical Tracking Systems to White Sand Missile Range for test and evaluation before production.

Photo-Sonics Early Cine Sextant at U.S. Navy Point Mugu

Photo-Sonics Cine Sextant At Vandenberg AFB

Photo-Sonics Super RADOT Tracking System at Ronald Reagan Ballistic Missile Defense Test Site

An Office in the UK

By 1973, the high speed camera business around the world had grown exponentially and so an international office was opened in the UK.

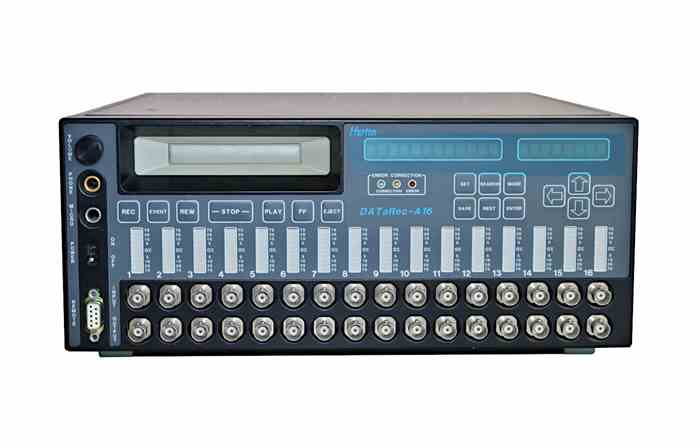

Over time the new organisation diversified, supporting its aerospace clients with flight test recorders from Heim. The first recording system came from the A series analogue recorders which were later followed by the D series digital recorders. Many tens of the Heim DATaRec-D4 series recorders were sold and thus established Photo-Sonics in the field.

Since then, Photo-Sonics International have been supplying instrumentation systems to the Aerospace, Military, Ministry, Academic and Automotive communities throughout the world. This 40+ years experience, provides us with an in-depth understanding of our customers requirements and helps us to propose practical solutions which are compliant and cost effective.

The management of Photo-Sonics International is structured to ensure that we are an effective sales and after sales support operation, with full involvement and technical know how.

To confirm our commitment to our customers we accepted the need for ISO 9000 accreditation and this was achieved in 1993. Since that time we have maintained our accreditation status and are now accredited to ISO 9001:2015.

Because of our recognised support capability we have been selected by several major defence organisations to carry out long term maintenance contracts on instrumentation equipment we have supplied. Examples include the maintenance, repair, calibration and support for the Royal Air Force, Leonardo UK, QinetiQ and BAE Systems.

Photo-Sonics International Ltd., Thame, Oxfordshire, UK.

Heim DATaRec-A16

Heim DATaRec-D4

Can we help?

Please get in touch with us today to take advantage of our wealth of experience and cutting-edge technology.